Introducing Galxe 2.0 – the future of manufacturing.

Are you ready to take your manufacturing operations to the next level?

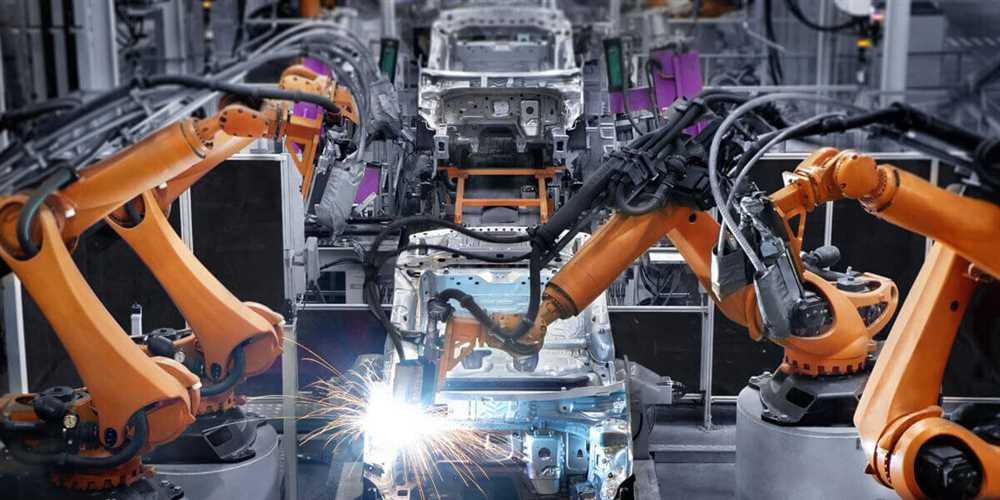

Galxe 2.0 is here to transform the manufacturing industry with its revolutionary intelligent robots. Powered by advanced AI and cutting-edge technology, Galxe 2.0 is set to redefine the way manufacturing processes are carried out.

Say goodbye to inefficiency and errors, and say hello to precision and productivity.

With Galxe 2.0, your factory operations will become faster, smoother, and more efficient than ever before. These intelligent robots are capable of handling complex tasks with ease, ensuring higher accuracy and quality control throughout the entire manufacturing process.

Experience a new level of automation and optimization.

Equipped with state-of-the-art sensors and intelligent algorithms, Galxe 2.0 robots can adapt to changing environments and make real-time decisions. They can seamlessly collaborate with human workers, enhancing productivity and safety on the factory floor.

Take the lead in the manufacturing industry.

By embracing Galxe 2.0, you’ll be stepping into the future of manufacturing. Stay ahead of the competition, streamline your operations, and deliver unmatched results to your customers.

Transform your manufacturing processes with Galxe 2.0 – the ultimate solution for intelligent automation.

Overview

Welcome to Galxe 2.0, the leading company revolutionizing the manufacturing industry with intelligent robots. With our cutting-edge technology and innovative solutions, we are transforming the way manufacturing processes are carried out, maximizing efficiency and productivity while minimizing costs and errors.

At Galxe 2.0, we understand the challenges that manufacturers face in today’s fast-paced and competitive market. Traditional manufacturing methods are often slow, labor-intensive, and prone to human error. This is where our intelligent robots come in.

Our advanced robotics systems are designed to automate various manufacturing tasks, from assembly and packaging to quality control and logistics. These robots are equipped with state-of-the-art sensors, artificial intelligence, and machine learning algorithms, allowing them to adapt and learn from their environment.

By harnessing the power of intelligent robots, Galxe 2.0 is able to greatly improve efficiency and precision in the manufacturing process. Our robots are capable of performing tasks with higher speed and accuracy than their human counterparts, resulting in faster production cycles and higher product quality.

Furthermore, our intelligent robots can work seamlessly alongside human workers, creating a collaborative and symbiotic relationship. They can perform repetitive and monotonous tasks, freeing up human workers to focus on more complex and creative endeavors. This not only increases overall productivity but also enhances job satisfaction and reduces the risk of workplace injuries.

Benefits of Galxe 2.0 Intelligent Robots:

- Increase in productivity and efficiency.

- Reduction in errors and defects.

- Faster production cycles.

- Improved product quality and consistency.

- Enhanced workplace safety.

- Optimization of resources and cost savings.

Our Solutions:

Galxe 2.0 offers a range of customizable robotics solutions tailored to meet the specific needs of manufacturing companies. Whether you need a complete overhaul of your production process or just a few robotic systems to augment your existing operations, we have the expertise and technology to deliver.

Contact us today to learn more about how Galxe 2.0 can revolutionize your manufacturing industry with intelligent robots.

Benefits

The Galxe 2.0 Intelligent Robots are revolutionizing the manufacturing industry by offering a wide range of benefits. Here are some of the advantages of integrating these intelligent robots into your manufacturing processes:

Increased Efficiency and Productivity

With Galxe 2.0 Intelligent Robots, you can boost the efficiency and productivity of your manufacturing operations. These robots are equipped with advanced AI technology, allowing them to perform tasks with precision and accuracy. By automating repetitive and labor-intensive tasks, the robots can significantly reduce production time and increase output.

Improved Quality Control

The intelligent robots are equipped with advanced sensors and cameras that enable them to detect defects and anomalies in real-time. This ensures that the manufactured products meet high-quality standards. By implementing Galxe 2.0 Intelligent Robots, you can significantly reduce the number of defective products and improve overall product quality.

These robots can also perform detailed inspections at a faster rate, minimizing the chance of human errors and ensuring consistent quality control.

In addition to these benefits, integrating Galxe 2.0 Intelligent Robots into your manufacturing processes can also lead to reduced operational costs, increased worker safety, and improved overall efficiency.

Upgrade your manufacturing industry with Galxe 2.0 Intelligent Robots and experience the transformational power they bring to your business.

Improving Efficiency and Productivity in the Manufacturing Industry

In today’s highly competitive manufacturing industry, efficiency and productivity are key factors for success. With the introduction of Galxe 2.0, a revolutionary intelligent robot, businesses can now enhance their operations and achieve significant improvements in efficiency and productivity.

Streamlining Operations

Galxe 2.0 has been designed to streamline various manufacturing processes, reducing the time and effort required for each task. This intelligent robot is equipped with advanced algorithms and machine learning capabilities, allowing it to analyze and optimize workflows in real-time. By identifying inefficiencies and bottlenecks, Galxe 2.0 can suggest process improvements, ultimately leading to a more streamlined and efficient manufacturing operation.

Increasing Accuracy and Speed

One of the main advantages of Galxe 2.0 is its ability to perform precise and repetitive tasks with high accuracy. Unlike human workers, this intelligent robot does not experience fatigue or make errors due to human factors. By leveraging Galxe 2.0’s capabilities, businesses can ensure consistent and accurate results, leading to improved product quality and customer satisfaction. Moreover, Galxe 2.0 can also significantly increase the speed of manufacturing processes, allowing for greater output and productivity.

With Galxe 2.0 revolutionizing the manufacturing industry, businesses now have the opportunity to optimize their operations and achieve higher levels of efficiency and productivity. By leveraging the power of intelligent robots, businesses can stay ahead of the competition and achieve new heights of success.

Applications

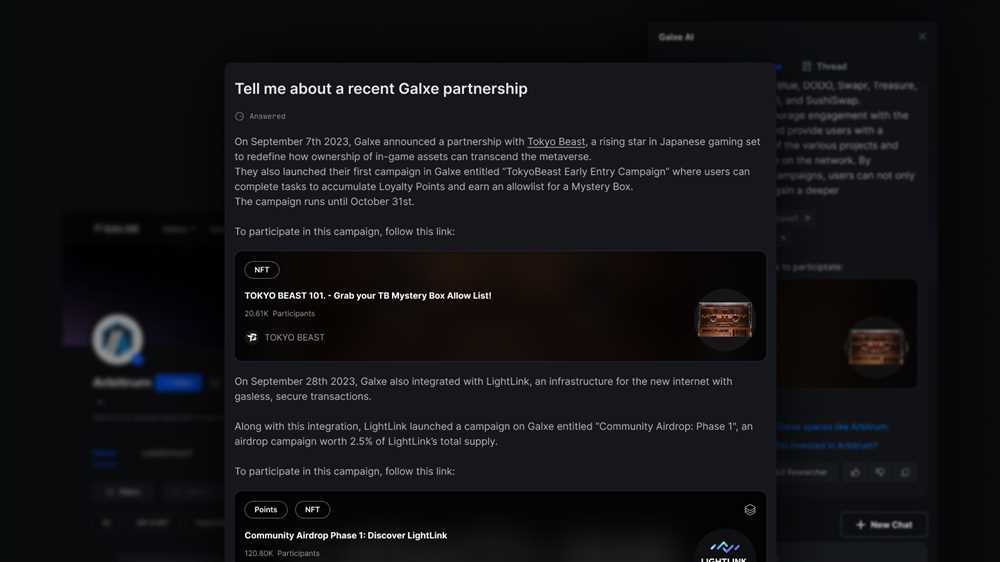

The Galxe 2.0 intelligent robots have unlimited applications across various industries, revolutionizing the manufacturing industry with their advanced capabilities. Here are some of the key applications of Galxe 2.0:

1. Assembly Line Automation

Galxe 2.0 robots can be used to automate assembly line processes in different manufacturing industries. These robots are equipped with cutting-edge sensors and intelligent software that enable them to perform complex tasks with precision and efficiency.

2. Quality Control

By utilizing their advanced vision systems and machine learning algorithms, Galxe 2.0 robots can significantly improve quality control in manufacturing. They can inspect products for defects, measure dimensions accurately, and identify any inconsistencies or anomalies in the production process.

With the ability to work tirelessly without fatigue or errors, these robots ensure that every product meets the highest standards of quality.

3. Material Handling

Galxe 2.0 robots are capable of handling various materials, including heavy objects, delicate components, and hazardous substances. They can safely and efficiently move materials between different workstations, reducing the risk of accidents and injuries.

4. Packaging and Palletizing

The intelligent robots can automate packaging and palletizing tasks, optimizing the efficiency and speed of these processes. They can accurately pick and place products or packages of different shapes and sizes, ensuring proper stacking and arranging.

This not only saves time and labor costs but also minimizes the risk of packaging errors and damage during transportation.

By leveraging the Galxe 2.0 intelligent robots, manufacturing companies can achieve higher production rates, improve product quality, and enhance overall operational efficiency. These robots are the future of the manufacturing industry, offering endless possibilities for automation and innovation.

Utilizing Intelligent Robots in Various Manufacturing Processes

Intelligent robots have revolutionized the manufacturing industry, offering a wide range of capabilities and efficiencies. These robots are equipped with advanced sensors, precision tools, and artificial intelligence algorithms that enable them to perform complex tasks with precision and accuracy.

One of the key areas where intelligent robots are being utilized is in assembly processes. These robots can assemble intricate components with ease, significantly reducing the time and effort required. They can handle delicate parts and ensure proper alignment, resulting in higher quality products.

Another important application of intelligent robots is in material handling. These robots can efficiently move heavy objects, load and unload materials, and transport products within the manufacturing facility. By automating these tasks, manufacturers can improve productivity, reduce the risk of injuries, and optimize space utilization.

Intelligent robots also play a crucial role in quality control processes. With their advanced sensors and computer vision technology, these robots can inspect products for defects, measure dimensions, and detect any inconsistencies. This helps manufacturers maintain strict quality standards and prevent faulty products from reaching the market.

In addition, intelligent robots are being utilized in welding and fabrication processes. These robots can perform intricate welding tasks with precision and accuracy, resulting in high-quality welds. They can also handle heavy and bulky materials, making them ideal for fabrication tasks that require strength and endurance.

Overall, the use of intelligent robots in various manufacturing processes offers numerous benefits such as increased productivity, improved product quality, reduced costs, and enhanced worker safety. As technology continues to advance, we can expect these robots to play an even bigger role in shaping the future of manufacturing.

| Improved Productivity | Enhanced Worker Safety | Reduced Costs |

| Higher Product Quality | Optimized Space Utilization | Strict Quality Standards |

Question-answer:

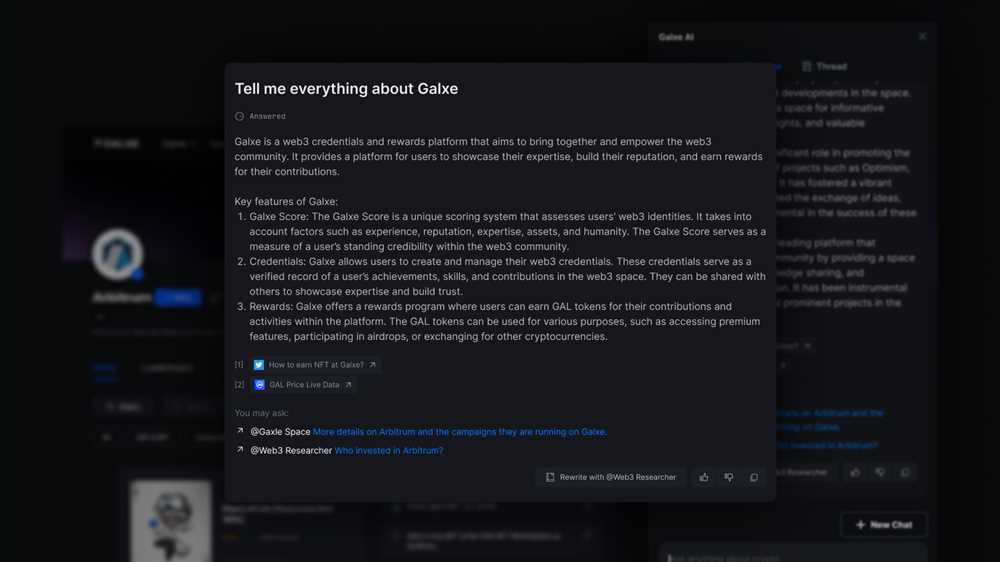

What is Galxe 2.0 Revolutionizing Manufacturing Industry with Intelligent Robots?

Galxe 2.0 is a state-of-the-art robotic system that is revolutionizing the manufacturing industry. It combines advanced robotics technology with artificial intelligence to create intelligent robots that can perform complex tasks with high precision and efficiency. With Galxe 2.0, manufacturers can streamline their production process, increase productivity, and reduce costs.

How does Galxe 2.0 revolutionize the manufacturing industry?

Galxe 2.0 revolutionizes the manufacturing industry by introducing intelligent robots that can perform tasks with precision and efficiency. These robots are equipped with advanced sensors and artificial intelligence algorithms that allow them to adapt to changing environments and make autonomous decisions. This eliminates the need for manual labor and increases productivity. Additionally, Galxe 2.0 can be easily integrated into existing manufacturing processes, making it a cost-effective solution for manufacturers.

What are the benefits of using Galxe 2.0 in manufacturing?

There are several benefits of using Galxe 2.0 in manufacturing. Firstly, it increases productivity by automating repetitive and complex tasks. This allows manufacturers to produce more goods in less time. Secondly, Galxe 2.0 improves product quality by performing tasks with high precision and consistency. Thirdly, it reduces costs by eliminating the need for manual labor and minimizing errors. Finally, Galxe 2.0 improves workplace safety by taking over hazardous tasks and reducing the risk of accidents.

Can Galxe 2.0 be customized for specific manufacturing processes?

Yes, Galxe 2.0 can be customized to meet the specific needs of different manufacturing processes. It is designed to be flexible and adaptable, allowing manufacturers to configure it for various tasks and environments. The robots can be programmed with specific algorithms and trained to perform specific actions. Additionally, Galxe 2.0 supports integration with other manufacturing systems and equipment, making it easier to incorporate into existing processes.