In today’s fast-paced world, industries heavily rely on the smooth functioning of their machinery and equipment to meet production targets and ensure customer satisfaction. However, unforeseen breakdowns and maintenance delays can wreak havoc, causing significant losses in terms of time and revenue.

That’s where Galxe 2.0 comes into play with its cutting-edge technology in predictive maintenance and fault detection. By leveraging advanced analytics and machine learning algorithms, Galxe 2.0 provides industries with unparalleled insights into the health and performance of their assets.

With Galxe 2.0, businesses can now move from traditional reactive maintenance practices to a proactive approach, reducing downtime and increasing operational efficiency. By continuously monitoring key parameters and detecting early signs of failure, Galxe 2.0 empowers maintenance teams to take preventive actions before major breakdowns occur.

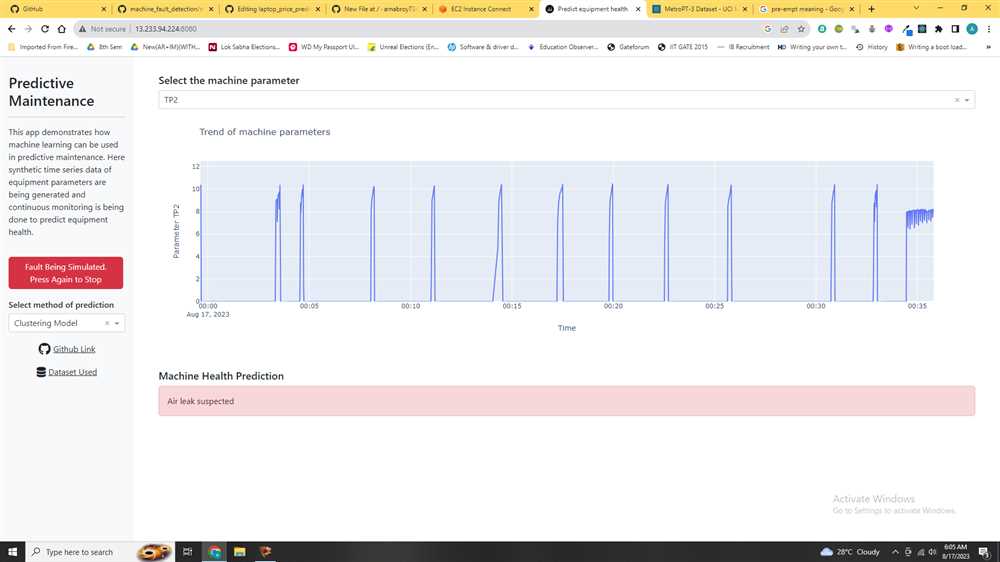

Furthermore, Galxe 2.0 offers real-time data visualization and predictive analytics, enabling businesses to make informed decisions based on accurate and up-to-date information. With customizable dashboards and alerts, managers can stay on top of asset performance and plan their maintenance activities accordingly.

In conclusion, Galxe 2.0 revolutionizes the field of predictive maintenance and fault detection, empowering industries to optimize their operations and improve their bottom line. By harnessing the power of data and analytics, Galxe 2.0 paves the way for a future where breakdowns and maintenance delays become a thing of the past.

Introducing Galxe 2.0: Revolutionizing Predictive Maintenance

Galxe 2.0 is the latest breakthrough in predictive maintenance and fault detection technology. With its advanced algorithms and machine learning capabilities, Galxe 2.0 is set to revolutionize the way industries approach maintenance and reduce downtime.

Advanced Algorithms for Unparalleled Accuracy

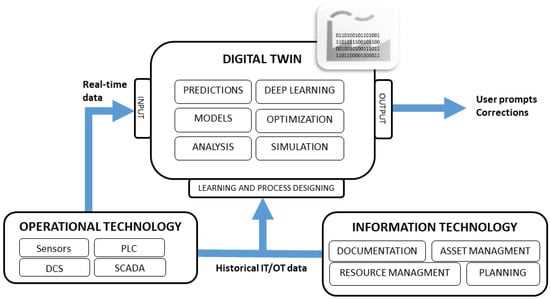

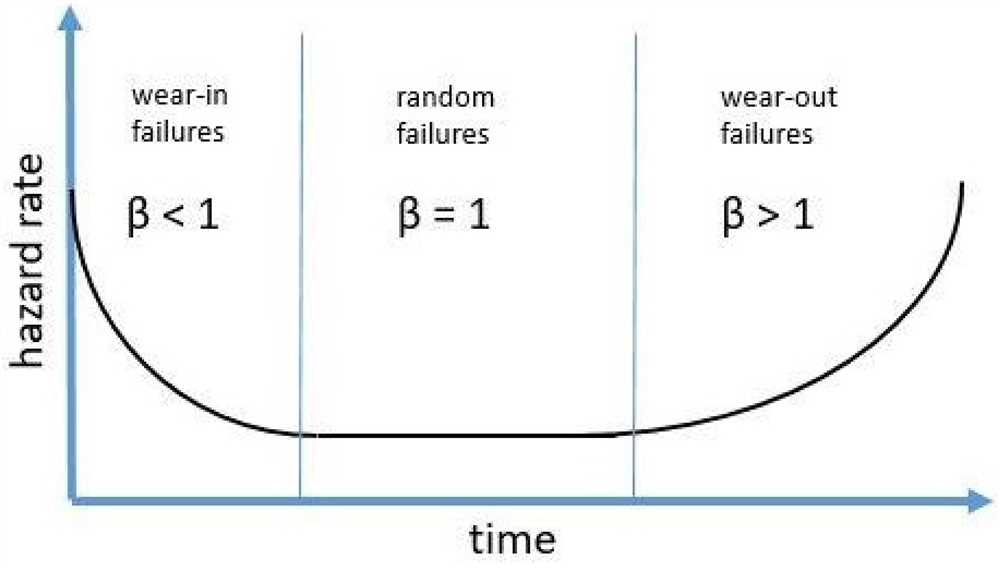

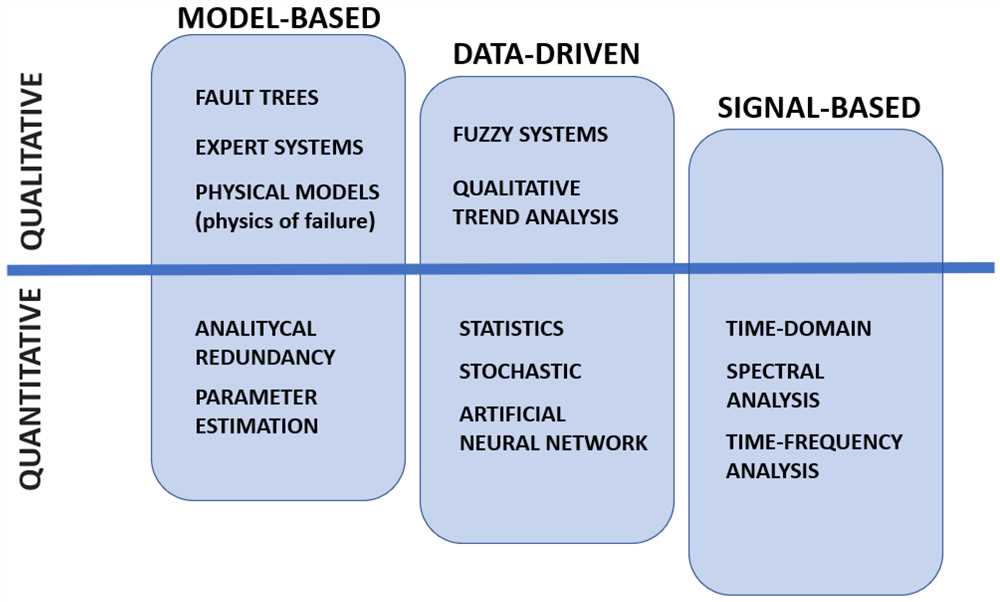

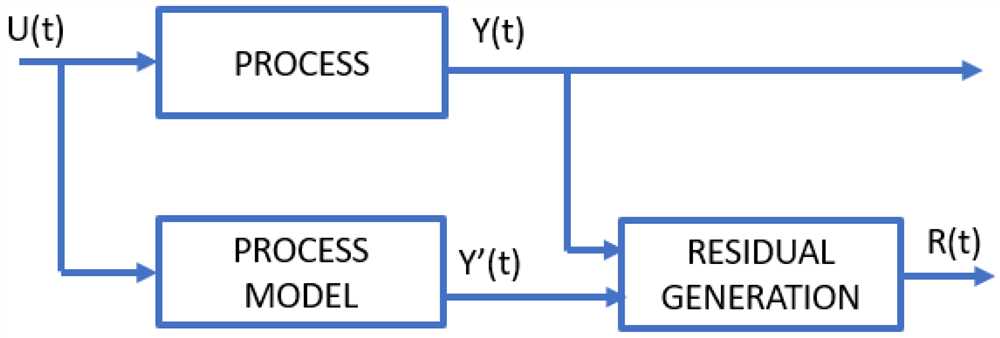

Galxe 2.0 boasts a powerful set of advanced algorithms that have been meticulously developed and fine-tuned to deliver unparalleled accuracy in predicting equipment failures and detecting faults. By analyzing vast amounts of data, including sensor readings, historical performance data, and maintenance records, Galxe 2.0 is able to identify patterns and indicators of potential issues with unprecedented precision.

Proactive Maintenance for Optimized Performance

Instead of relying on reactive maintenance practices, Galxe 2.0 enables businesses to adopt a proactive approach by highlighting potential issues before they escalate into costly failures. By detecting early warning signs and notifying maintenance teams in real-time, Galxe 2.0 empowers businesses to take prompt action to prevent equipment breakdowns and optimize overall performance.

By implementing Galxe 2.0, companies can minimize unplanned downtime, increase operational efficiency, and reduce maintenance costs. Galxe 2.0 is the ultimate solution for businesses seeking to stay ahead of maintenance challenges and maximize the lifespan of their equipment.

Enhanced Features for Unparalleled Fault Detection

Galxe 2.0 takes fault detection to new heights with its enhanced features that ensure unparalleled accuracy and reliability. Our cutting-edge technology is designed to identify potential faults in machinery before they become critical, allowing for timely maintenance and preventing costly breakdowns.

Advanced Analytics

With Galxe 2.0, we have implemented advanced analytics algorithms that enable us to analyze complex data patterns and detect even the smallest abnormalities. By analyzing historical data and comparing it with real-time readings, our system can identify deviations from normal behavior and pinpoint potential faults with a high level of precision.

Machine Learning Algorithms

Our fault detection system utilizes machine learning algorithms that continuously learn and improve over time. By training on large amounts of data, our algorithms can detect patterns and anomalies that may indicate impending faults. This allows us to adapt to changing machinery conditions and provide accurate fault detection even in dynamic operating environments.

Furthermore, our machine learning algorithms can identify patterns that are too complex for traditional rule-based systems. This means that even subtle and subtle faults can be detected early on, reducing the risk of equipment failure and minimizing downtime.

With Galxe 2.0’s enhanced features for fault detection, businesses can benefit from improved operational efficiency, reduced maintenance costs, and increased equipment reliability. By utilizing advanced analytics and machine learning algorithms, Galxe 2.0 offers unparalleled accuracy in predicting and preventing faults, making it the ideal solution for any industry.

Cost-effective Solution for Industrial Predictive Maintenance

In today’s rapidly evolving industrial landscape, predictive maintenance has emerged as a crucial strategy for ensuring equipment reliability and minimizing downtime. By leveraging advanced data analytics and machine learning algorithms, companies can monitor the health of their machinery and detect potential faults before they lead to costly breakdowns.

However, implementing a predictive maintenance system can be a major investment for companies, especially those with a large number of assets. The costs associated with installing sensors, collecting and storing data, and developing predictive models can quickly add up.

The Galxe 2.0 Advantage

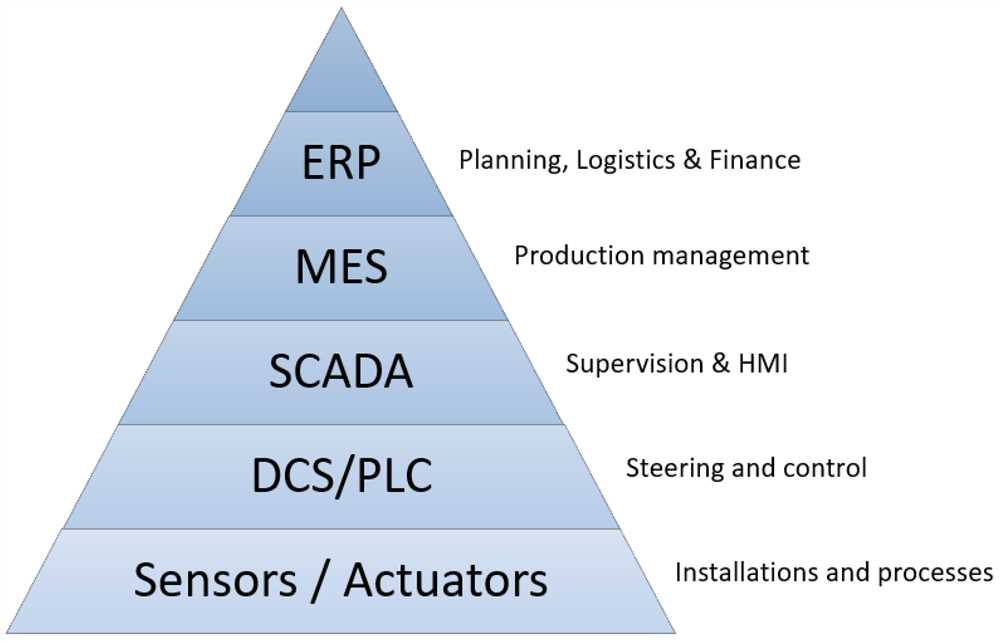

Enter Galxe 2.0, a cost-effective solution for industrial predictive maintenance. With its cutting-edge technology, Galxe 2.0 eliminates the need for expensive sensor installations by leveraging existing data sources within the company’s infrastructure. Through integration with various data streams, such as SCADA systems and IoT devices, Galxe 2.0 captures and analyzes real-time data to detect anomalies and predict equipment failures.

Furthermore, Galxe 2.0 offers a scalable and flexible platform that can adapt to the unique needs of any industry. It utilizes machine learning algorithms to continuously learn and improve its predictive capabilities, allowing for accurate fault detection and diagnosis.

Benefits of Galxe 2.0

By adopting Galxe 2.0, companies can enjoy a range of benefits, including:

- Reduced maintenance costs by eliminating unnecessary repairs and optimizing maintenance schedules

- Minimized downtime through early fault detection and faster response times

- Increased equipment lifespan by proactively identifying potential issues and taking preventive measures

- Improved operational efficiency by optimizing asset utilization and resource allocation

- Enhanced safety by addressing potential safety hazards before they cause accidents

With its cost-effectiveness and powerful predictive capabilities, Galxe 2.0 is revolutionizing the field of industrial predictive maintenance. Companies can now reap the benefits of data-driven maintenance strategies without breaking the bank.

Improved Efficiency and Downtime Reduction with Galxe 2.0

Galxe 2.0 brings a new level of efficiency and operational excellence to the field of predictive maintenance and fault detection. By leveraging advanced machine learning algorithms and real-time data analysis, Galxe 2.0 is able to identify potential equipment failures early on, allowing for timely repairs and preventing costly downtime.

Efficiency Optimization

With Galxe 2.0, businesses can optimize their operations and achieve higher levels of efficiency. By continuously monitoring equipment performance and analyzing historical data, Galxe 2.0 is able to identify areas where efficiency can be improved. This allows businesses to make informed decisions on process optimization, leading to increased productivity and reduced costs.

Galxe 2.0 also offers real-time alerts and notifications, enabling maintenance teams to address potential issues proactively. By addressing problems at an early stage, businesses can prevent major breakdowns and minimize the impact on production.

Downtime Reduction

One of the biggest challenges in industrial operations is unplanned downtime. It can be costly and disruptive, impacting productivity and profitability. Galxe 2.0 is designed to tackle this challenge head-on.

With its advanced predictive maintenance capabilities, Galxe 2.0 can forecast equipment failures before they occur. By analyzing sensor data and identifying patterns, Galxe 2.0 can detect anomalies and predict when a machine is likely to fail. This enables maintenance teams to intervene proactively, schedule repairs, and prevent unexpected downtime.

By leveraging Galxe 2.0, businesses can effectively reduce unplanned downtime and optimize their maintenance schedules. This leads to improved operational efficiency, increased equipment reliability, and enhanced overall productivity.

In conclusion, Galxe 2.0 revolutionizes the field of predictive maintenance and fault detection by offering improved efficiency and downtime reduction. With its advanced analytics capabilities, businesses can optimize their operations, increase efficiency, and minimize unexpected downtime. Galxe 2.0 is the ideal solution for any business looking to improve their maintenance practices and achieve operational excellence.

Question-answer:

What is Galxe 2.0?

Galxe 2.0 is an advanced system for predictive maintenance and fault detection.

How does Galxe 2.0 work?

Galxe 2.0 uses machine learning algorithms to analyze data from various sensors and predict when maintenance is needed or when a fault may occur.

What are the benefits of using Galxe 2.0 for predictive maintenance?

Using Galxe 2.0 for predictive maintenance can help reduce downtime, increase equipment lifespan, and improve overall operational efficiency.